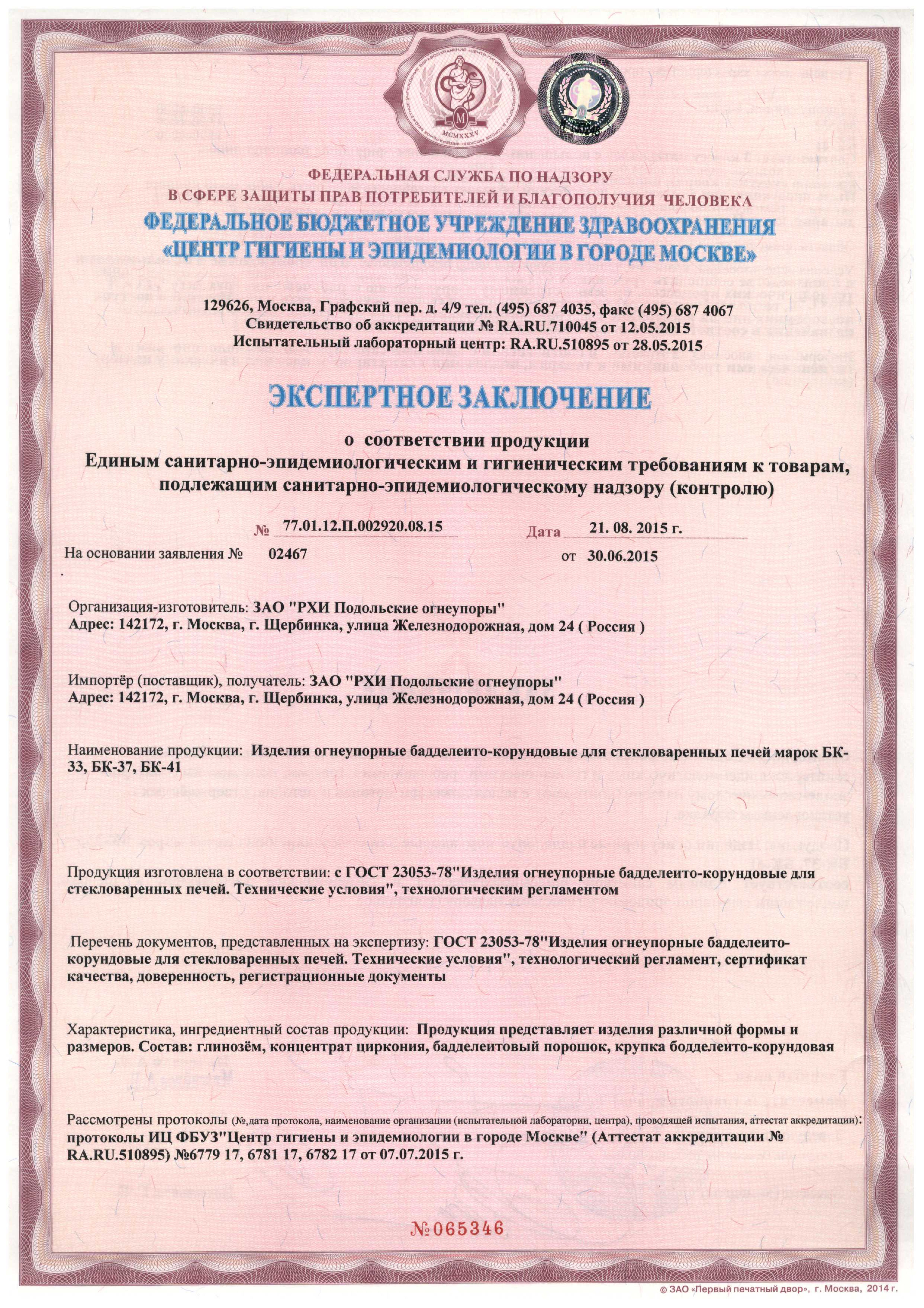

Fused-cast alumina-zirconia-silica products (AZS or Bacors) are the most common material for construction of glass melting furnaces (baths and critical areas of superstructure). A distinguished feature of AZS refractories is high glass-attack resistance, refractoriness, and durability. Use of fused cast refractories for constructing baths of glass melting furnaces enables application of glass melting temperatures within the range of 1500 to 1600 °C.

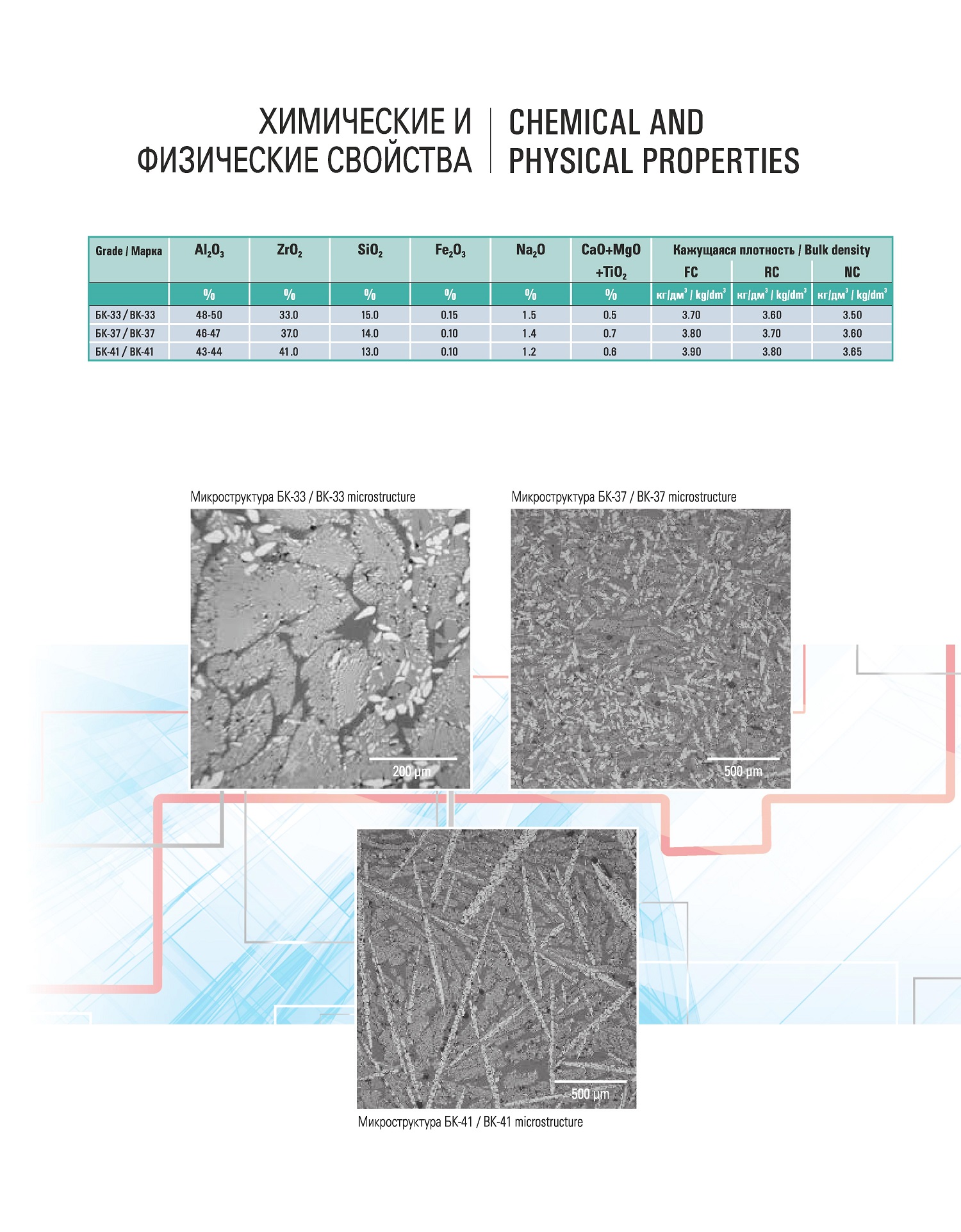

AZS refractories are Al2O3–ZrO2–SiO2 system products. The range of compositions of Bacor refractories containing from 33 to 41% ZrO2 is determined by the position of ternary eutectic having melting point of 1765 °C.

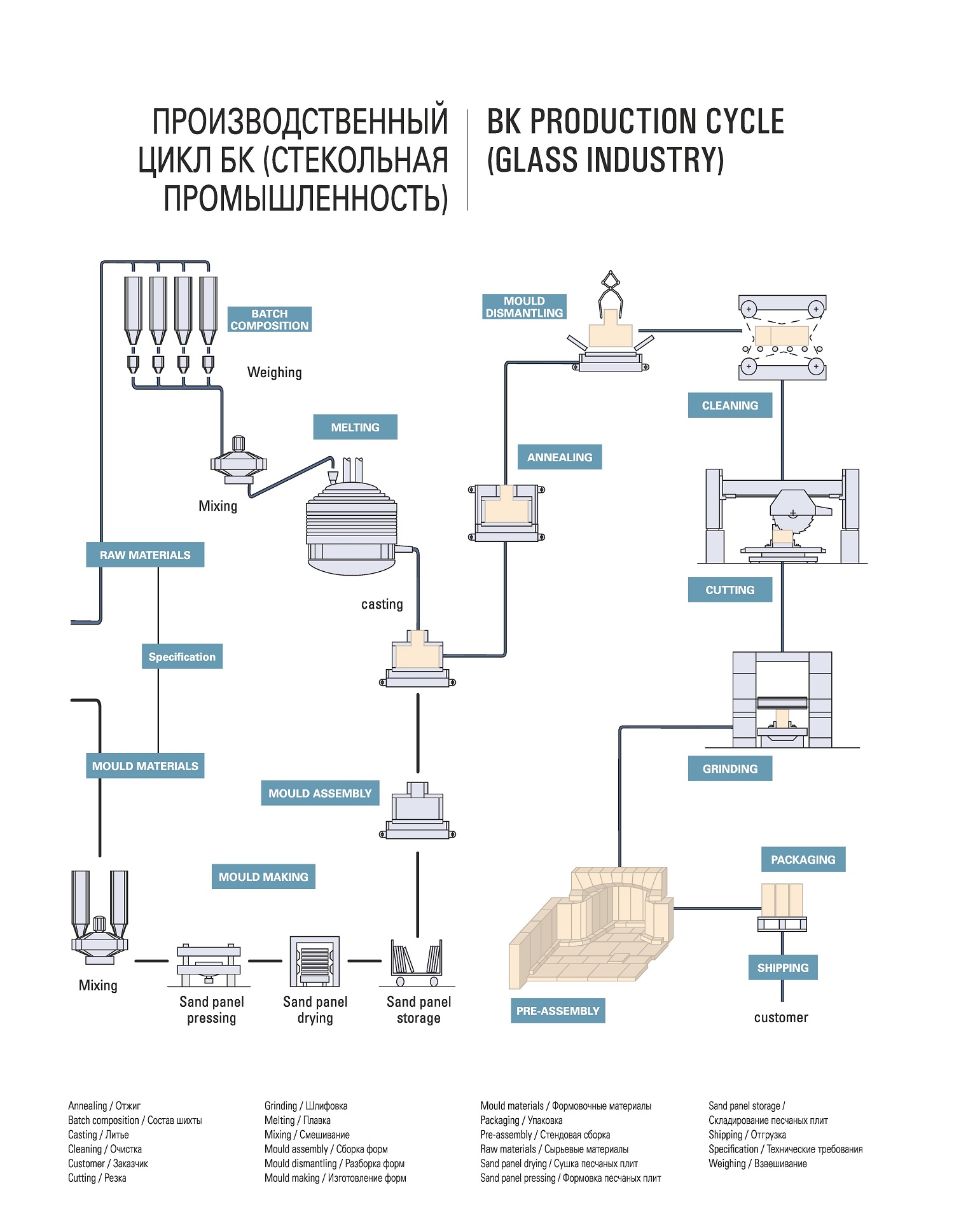

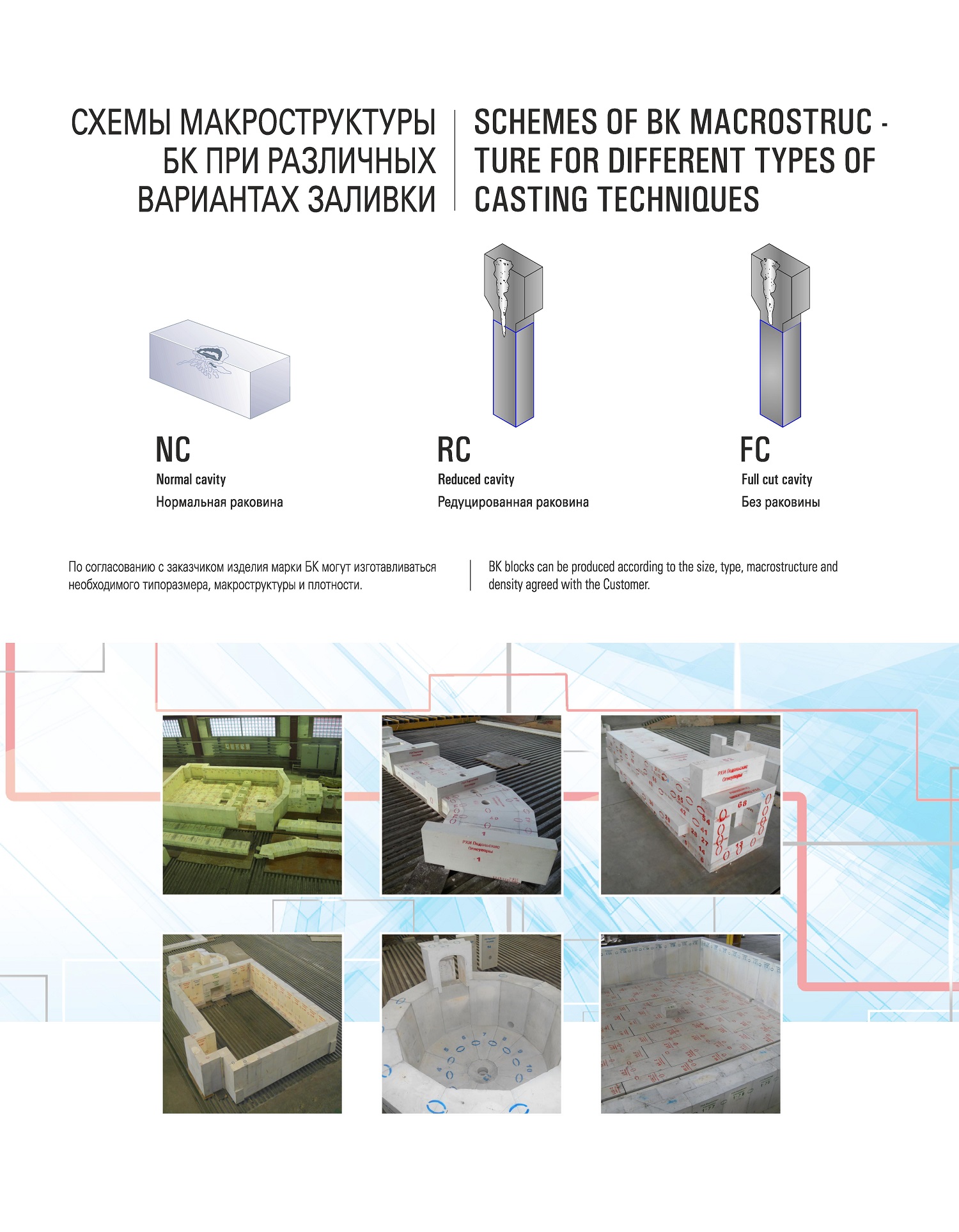

Raw materials for Bacor production are zircon concentrate, alumina, and natural baddeleyite. The fused cast refractories manufacturing technology includes charge melting in an electric arc furnace, melt spouting into molds, annealing and machining of products.